Harvest Right Freeze Dryers are designed to freeze-dry food, preserving it by removing moisture. Freeze-drying involves freezing the food, reducing the pressure, and then warming it slightly so that the frozen water sublimates directly from ice to vapour without passing through the liquid phase. This process preserves the food for extended periods (up to 25 years or more), maintaining its nutritional content, flavor, and texture.

Harvest Right Commercial Freeze Dryer

High-Capacity Tray System

The HRC100 boasts nine 18"x26" industrial baking trays, providing a total shelf area of 4,270.5 square inches. This expansive capacity enables the processing of 65-90 pounds of fresh food per batch.

Integrated Vacuum System

The freeze dryer comes equipped with a premier industrial vacuum pump inside the unit, ensuring optimal performance and space efficiency.

Innovative Mid-Size Design

As the only mid-size freeze dryer of its kind in the industry, the HRC100 fills a crucial gap in the market, offering advanced technology at an accessible price point.

Proven Technology

Built on Harvest Right's established expertise, the HRC100 utilizes proven freeze-drying technology, guaranteeing reliable and consistent results.

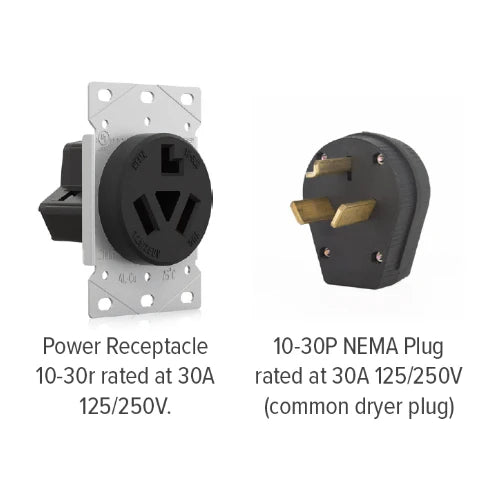

Power Requirements

220 volt single phase outlet. A dedicated 30 amp circuit is required.

CE certified breaker: GFCI, overload protection, short circuit protection, isolation, residual current operation.

HRC 100 Frequently Asked Questions

Q: What is the capacity of the HRC100 Freeze Dryer?

A: The HRC100 can process 65-90 pounds of product per batch, depending on the specific product being freeze-dried.

Is the HRC100 suitable for commercial use?

A: Yes, the HRC100 is designed as a mid-size production unit for businesses looking to enter or expand their commercial freeze-drying operations.

Q: How easy is it to operate the HRC100?

A: The HRC100 is user-friendly. Simply load your product, press start, and the machine will alert you with a beep when the process is complete.

Q: What type of trays does the HRC100 use?

A: The HRC100 accommodates standard baking sheet trays.

Q: How does the HRC100 compare to industrial freeze dryers?

A: The HRC100 bridges the gap between small-scale and industrial freeze dryers, offering an affordable entry point into commercial freeze-drying without compromising on quality or capacity.

Q: Can the HRC100 help with scaling production?

A: Yes, the HRC100 is designed to create true redundancy in freeze-drying operations, providing businesses with the flexibility and capacity to meet growing demand.

Q: Is the HRC100 reliable for continuous operation?

A: The HRC100 is designed for exceptional performance and reliability, making it suitable for businesses that need consistent freeze-drying capabilities.

Q: What types of businesses can benefit from the HRC100?

A: Any business looking to enter or expand freeze-drying operations can benefit from the HRC100, particularly those seeking a mid-size solution between small-scale and industrial options.

Q: What are the power requirements for the HRC100?

A: The HRC100 requires a 220 volt outlet with a dedicated 30 amp circuit. It also needs a CE certified breaker that includes GFCI, overload protection, short circuit protection, isolation, and residual current operation.

Advantages of Freeze Dried Foods

-

Freeze Most Foods

Meals and Snacks

Freeze dried entire meals ready to eat in the future.

Fruits and Vegetables

Freeze dry fruits and veggies to add into meals or to eat as a snack.

Desserts and Treats

Freeze dry ice cream and many candies (such as skittles) for something fun to eat for the whole family. -

Better Food Preservation

Unmatched Shelf Life

Preserve foods for up to 25 years.Better Flavour and Quality

Freeze drying preserves up to 97% of the texture, flavour, and nutrition unlike canning.Nutrient Retention

Nearly all nutrients are preserved during the freeze dry process. -

Better Storage and Portability

Storage Options

Freeze Dried Foods can be stores in a variety of ways depending on your needs.Highly Portable

Freeze dried foods weigh far less making storage easier. Bagged freeze dried foods are also far more portable for road trips, hiking, camping or for emergencies should you have to evacuate.

Watch Now: 'Harvest Right' Freeze Dryer Unboxing & Setup

Which freeze dryer do you need?

-

Small

Trays: 4

Food Per Batch: 6-10 lbs.

Food Per Year: Up to 1800 lbs.

Tray Space: 434 sq. inches

Dimensions (l/w/h): 26.8"x17.4"x 21.5"

Weight: 98 lbs

Power: 110V -

Medium

Trays: 5

Food Per Batch: 10-15 lbs.

Food Per Year: Up to 3000 lbs.

Tray Space: 675 sq. inches

Dimensions (l/w/h): 19'x25"x29"

Weight: 127 lbs

Power: 110V -

Large

Trays: 6

Food Per Batch: 18-27 lbs.

Food Per Year: Up to 5000 lbs.

Tray Space: 1107 sq. inches

Dimensions (w/d/h): 21.3"x27.5"x31.3"

Weight: 143 lbs

Power: 20 amp -

XL

Trays: 6

Food Per Batch: 40-50 lbs.

Food Per Year: Up to 10,000 lbs.

Tray Space: 2251 sq. inches

Dimensions (w/d/h): 24.3"x37.4"x35.6"

Weight: 258 lbs

Power: A dedicated 20 amp circuit (NEMA 5-20) outlet. -

Commercial

Trays: 9

Food Per Batch: 65-90 lbs.

Food Per Year: Up to 10,000 lbs.

Tray Space: 2251 sq. inches

Dimensions (w/d/h): 70"x33.5"x37.25

Weight: 985 lbs

Power: NEMA 10-30P, dedicated 30A circuit required.

FAQ's

How do freeze dryers work?

Freeze dryers work by preserving perishable materials by removing water through a process called freeze drying (or lyophilization). Freeze drying uses the following processes:

Freezing - Items are cooled to a very low temperature (below freezing). This causes the water inside the material to form ice crystals.

Primary Drying (Sublimation) - Pressure in the chamber is reduced (creating a vacuum), and the temperature is slightly raised causing the ice to sublimate. The water goes directly from solid (ice) to vapour (gas) without passing through the liquid phase. This removes around 95% of the water content.

Secondary Drying (Desorption) - The remaining water, bound more tightly to the material, is removed by slightly raising the temperature while maintaining the vacuum. This step eliminates the last 1–5% of moisture content, ensuring the material is thoroughly dried.

What can you freeze in a freeze dryer?

Fruits and Vegetables:

- Strawberries

- Apples

- Bananas

- Blueberries

- Mangoes

- Peaches

- Raspberries

- Peas

- Corn

- Green beans

Meats and Proteins:

- Jerky (freeze-dried meat)

- Freeze-dried cheese

Meals and Snacks:

- Yogurt bites

- Granola with freeze-dried fruits

- Certain freeze-dried soups or meals (if the ingredients are small or can be eaten dry)

Desserts and Treats:

- Freeze-dried ice cream (astronaut ice cream)

- Many candies (especially Skittles)

Are there items you should not put into a freeze dryer?

Yes. Some items are not suitable to freeze dry. Some of these items are high fat, high sugar or are carbonated and include:

- High-Fat Foods such as butter, lard, oils and mayonnaise.

- High-Sugar Foods such as honey, syrups, jams / jellies.

- Alcoholic and Carbonated Beverages

- Pure Chocolate

- Soft Cheeses and Cream Cream

- Certain Candies with gelatin

- Chewing Gum

- Fresh Bread

What are the advantages and disavdantages of freeze drying?

Advantages of Freeze-Drying:

Nutrient Preservation: Freeze-drying retains up to 97% of the nutrients, flavour, and texture of foods, making it a healthy option for long-term storage.

Long Shelf Life: Freeze-dried foods can last for years—often 25 years or more—without refrigeration, making them ideal for emergency preparedness and food storage.

Lightweight and Compact: The removal of moisture makes freeze-dried foods significantly lighter and more compact, which is perfect for camping, hiking, or backpacking.

Versatility: A wide range of foods can be freeze-dried, including fruits, vegetables, meats, and complete meals, allowing for diverse meal options.

Convenient Rehydration: Freeze-dried foods are easy to rehydrate, requiring only water, and they often retain their original texture and flavour after reconstitution.

Disadvantages of Freeze-Drying:

High Initial Cost: Freeze-drying equipment can be expensive, which may not be feasible for everyone.

Time-Consuming Process: The freeze-drying process can take several hours to over a day, depending on the type and quantity of food.

Energy Consumption: Freeze-dryers can consume a significant amount of energy during operation.

Texture Variation: While freeze-drying retains flavour and nutrients, some foods may lose their original texture, making them less appealing to some people.

Requires Pre-Preparation: Foods often need to be pre-prepared (washed, sliced, or cooked) before freeze-drying, which adds an extra step to the process.